|

Hungary 2000

|

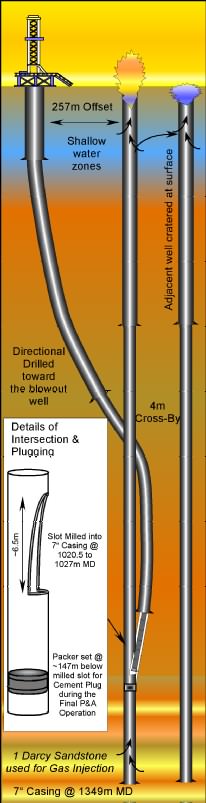

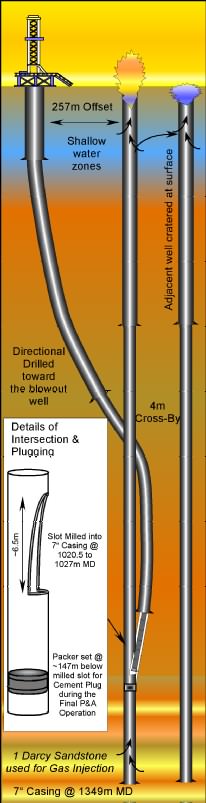

Problem:

During a workover on a well in a

gas storage field control of a swab kick was lost and a blowout and fire

resulted. Reservoir pressure was near seasonal high and production from the

well was predicted at ~3.8Mscm/day. The gas source was a pipeline from

Russia and the blowout well handled injection during the summer and

production during the winter. A 6m perforated interval at 1229m MD into a

Darcy+ permeability sandstone was the main production interval along with

possible communication with shallower zones having gas and water. The

Hungarian wild well firefighting team successfully capped the well in two

weeks. However, after the bullhead operation an adjacent well cratered and

the capping stack was opened to relief pressure. The casing had burst near

the surface and the resulting sand erosion destroyed the capping stack and

the well eventually cratered producing large volumes of formation water.

Other surface options were lost. |

| Remedial Strategy:

A relief well became the only

feasible control option and the initial plan developed included a single

relief well having a casing intersection followed by well killing and

plugging operations. A pit and trench to divert the ~3000m3/day of water was

initially constructed, but additional pits were dug to handle the effluent,

which could not be allowed to enter local water systems. Many wells were

present in this gas storage field and it was thought further damage to other

wells, subsequent gas resources and reservoir damage would occur if the well

was not controlled. A single relief well, having a ~257m offset, was chosen

to intersect, kill and plug the blowing well. |

| Special Services:

John Wright Company was contracted to provide both strategic and tactical

special services. Technical assistance and onsite supervision during the

initial diagnostic period and the P&A operations were provided. JWCO

supervised the special services required for the relief well intervention

project. This included pre-planning and on-site supervision of directional

drilling, surveying, kill operations and casing detection. Vector Magnetics,

responsible for electromagnetic ranging, was coordinated through JWCO on

this project and worked together as one team. Well Flow Dynamics was

instrumental in the diagnostic investigation and in simulating various

relief well kill scenarios for possible kill operations. |

Challenges: The project

was complicated by the following:

- The surface flow included

both water and gas into a crater, requiring control and storage of the

produced water from both deep and shallow zones.

- The reservoir pressure was

dropping considerably requiring a quick P&A .

- RW surface location was

restricted due to many wells, water trench and pits locations and other

environmental conditions.

- No surveys existed above

500m MD and the lower surveys being MSS at ~100m intervals, resulting in a

positional uncertainty of ~25m radius.

- Shallow gas

charging was not expected, but was considered

during planning and drilling.

|

Results:

- A 257m offset wellhead

required high build rates in the upper portion of the RW.

- The relief well located

the target well at ~650m and a 4m Cross-By was achieved followed by a

diverging path to the intersection point. At ~1020.5m MD

- A 6.5m slot was milled in

the target well’s 7” casing to allow the P&A operations.

- After opening the slot up,

a hydraulic set packer/bridge-plug was run and set ~ 147m below the slot

to stop the gas flow from the reservoir. This is the

first time this had every been done from a relief well.

- A cement plug was pumped

into from the packer/plug to just below the slot.

- A final cement plug was

pumped from the slot up to the shallow zone where the casing strings were

damaged

|