|

Southeast Asia 2002

|

Problem:

While

development drilling well control was lost and gas broached to the seabed

under the platform. The well subsequently bridged and the broach stopped. It

was later discovered that the tubing and all protective strings of casing in

a well adjacent to the blowout were severed below the conductor and open to

the sea. This left an unacceptable single well control barrier, a TRSSV in

the tubing and a packer in the 9-5/8” casing, to protect the platform from

another subsea broach.

|

| Remedial Strategy:

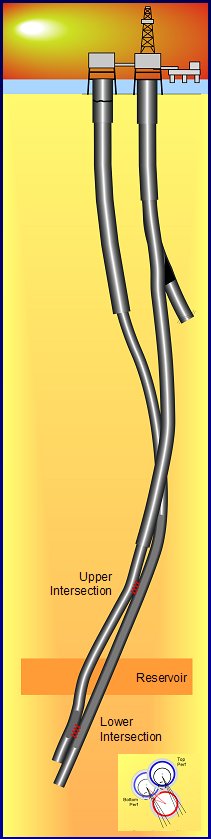

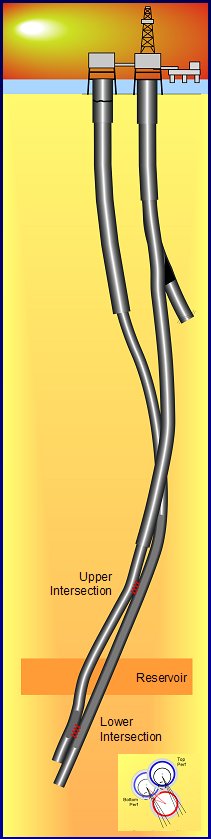

The

basic design strategy was to drill an intervention well from an adjacent

bridge-connected platform and intersect the problem well at its production

casing string both above and below the producing reservoir. After

intersection was confirmed using electromagnetic homing-in technology, the

wells would be perforated and cement circulated down the relief well

drillstring, through a cement retainer, up the problem well’s production

casing and back into the relief well’s annulus. As a final assurance, a

balanced cement plug would be set across the upper perforations and squeezed

into the problems well’s tubing. |

| Special Services:

John

Wright Company (JWCO) was contracted to supervise the special services for

the relief well to include: pre-planning, on-site supervision, directional

drilling, surveying, casing detection, intersection and kill hydraulics.

Well Flow Dynamics provided hydraulic modeling, Vector Magnetics provided

electromagnetic ranging services and SDI provided gyro surveys and gyro MWD.

All companies worked together with JWCO to create a single special services

team. |

Challenges: The project

was complicated by the following:

- The platform was

considered a worldwide critical asset by the owner and all operations were

designed with significant safety factors to protect the asset.

- Multiple contingency plans

were required for each operation.

- The problem well was a

directional well at 47° inclination with uncertain surveys. Subsequent to

the first intersection, the plan called for steering the relief well 400m

at 4m proximity to the problem well with significant magnetic

interference.

- Dual intersection

techniques required low incidence angles and exceptionally precise

directional control.

- A relief well of this type

had never been attempted before.

|

Results:

- The project was completed according to

plan without significant problems or delays.

- The special services team was integrated

seamlessly with the drilling team to create an effective and efficient

operation.

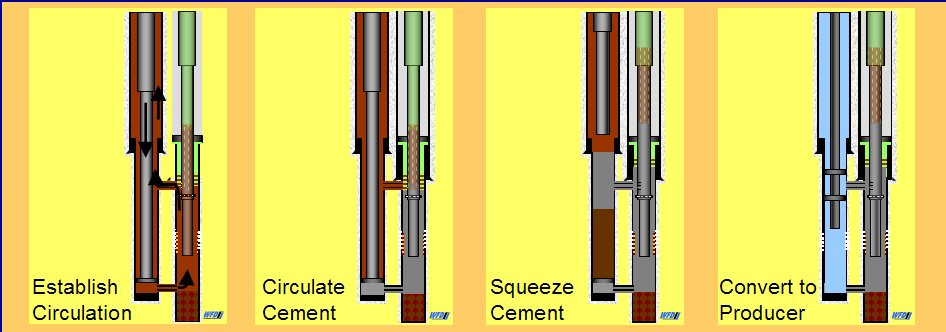

- The dual intersection was executed

without significant delays.

- Hydraulic communication was established

with oriented TCP guns at the upper and lower intersections.

- Cement was circulated from the relief well

into the casing and across the reservoir section of the problem well and

back into the relief well. Cement was squeezed into the upper

intersection.

- The relief well was converted into a

producing well.

|